Passing the BPI Exam With Energy Auditor Training

FREE BPI PRACTICE EXAMPUT YOUR HOME PERFORMANCE BUSINESS ON ROCKET FUELENERGY AUDITOR NEWSLETTERGet the only Energy Auditor Marketing Newsletter with monthly strategies and tactics to grow your home performance business.

The main topics of the BPI BA exam are listed out below. Click on a link that interests you, or you need some brushing up on to learn more on each subject.

1. Building Science Fundamentals 1a. Basic terms and definitions 1b. Principals of energy, air & moisture 1c. Combustion science 2. Buildings and Their Systems 2a. Building components 2b. Conservation strategies 2c. Comprehensive building assessment process 2d. Design considerations 3. Measurement and Verification of Building Performance 3a. Applied diagnostics and troubleshooting 4. BPI National Standards and Project Specifications 4a. Comprehensive building assessment 5. Analyzing Buildings Systems 5a. Comprehensive building assessment 5b. Appliances and lighting 6. Conduct and communications 6a. Conservation strategies |

BPI Written Exam - Section 2 Buildings and Their Systems

DHW is domestic hot water. Hot water tanks are either electric, gas, liquid petroleum, or oil powered. They are rated by their Energy Factor or EF for short. The energy factor is based:

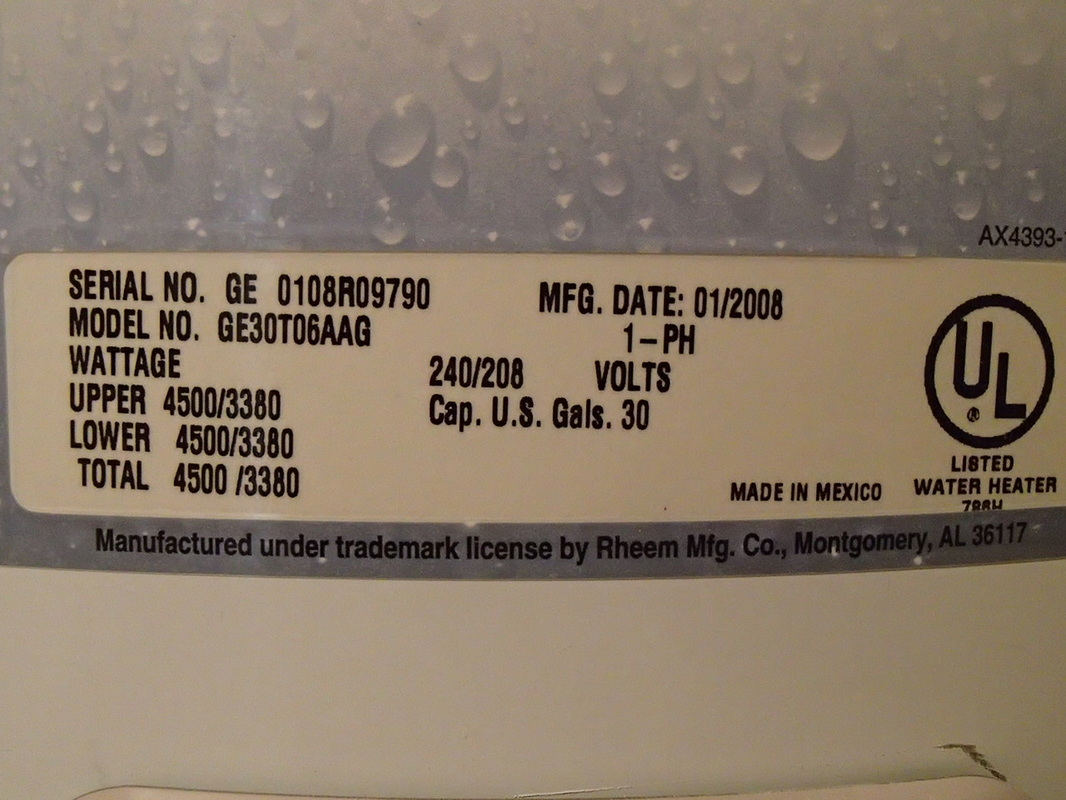

1) The recovery efficiency, or how efficiently the heat from the energy source is transferred to the water. Electric water heaters have a high recovery efficiency of 98% because the heating elements are surrounded by water, so very little is lost. Gas water heaters have a lower recovery efficiency of around 78%. 2) Stand-by losses, or the percentage of heat lost per hour from the stored water compared to the content of the water. The higher the insulation the lower the stand-by loss. 3) Cycling losses. Electric hot water tanks Electric water heaters typically have two heating elements (rods) on the bottom and top half of the tank (gray panels in the picture below). The panels can be removed (turn off the circuit breaker to the water heater before) and the temperature can be turned down using a screw driver if a lower water temperature is desired. Just make sure you don't go below 120 degrees F which is the temperature at which legionnaires bacteria can start growing in the water pipes. These tanks will also have a dip stick anode rod which is meant to rust out first, slowing down the rust that builds up along the tank walls. These can be replaced but it is also a good idea to flush the tank once a year if it is newer. Older tanks may already have a layer of rust and trying to flush out the tank may disturb the rust can cause a leak in the tank. Water heaters are labeled with a yellow sticker that says the amount of energy they use for a family of 4. Usually the annual costs are between $400-$500 for a 50 gallon electric water heater. Sometimes the manufacturers label will say the year built, other times you will have to get it from the model number and a directory. The water heater tanks are insulated with R-3 to R-4 insulation foam. In cold climates it is cost effective to wrap the tank and the hot and cold water lines in an insulation wrap. This is because the water is kept hot all day long, whether you use the water or not and even if it is just sitting in the tank, the water looses it heat over time. Both electric and gas water heaters should have a pressure relief value which prevents a dangerous amount of pressure from building up in a tank. Gas hot water tanks

Gas water heaters use a pilot light (always on) and burner to heat the water indirectly. Along not as efficient as an electric water heater, natural gas is usually a lot cheaper and therefore use much less energy and cost less to operate than their electric counterparts. Next Section2a. Building Components

2b. Conservation Strategies

2c. Comprehensive Building Assessment Process

2d. Design considerations

|