Passing the BPI Exam With Energy Auditor Training

FREE BPI PRACTICE EXAMPUT YOUR HOME PERFORMANCE BUSINESS ON ROCKET FUELENERGY AUDITOR NEWSLETTERGet the only Energy Auditor Marketing Newsletter with monthly strategies and tactics to grow your home performance business.

|

BPI Written Exam - Section 1 Building Science Fundamentals4. Understand Combustion Safety Issues: Combustion Air, Draft, Worst Case / Baseline Depressurization, Spillage, Backdrafting, Unvented Combustion AppliancesCombustion AirAll orphan or naturally drafted combustion appliances require fresh air as part of their combustion process. (Sealed combustion appliances use a direct PVC vent to the outside to draw air in via a small fan). The fresh air comes simply from the surrounding room and any transfer grilles that connect the immediate room to other rooms or the outside.

An example of a orphan or naturally drafting water heater

If the appliances does not have enough combustion air, high CO levels may form and the unit will backdraft CO into the room. Several things can cause a shortage of combustion air:

DraftDraft is a naturally occurring process (think stack affect) that vents CO and combustion by-products from a gas appliance through the flue pipe and to the outside. The combustion by-products exit the appliance hot, and so they are carried up the flue stack. Upon appliance start-up however, the combustion gases still need time to warm-up, and this is the highest risk for those gases to back draft and enter into our living space.

That is why we test the draft pressure and spillage of a combustion appliance WITHIN THE FIRST 60 SECONDS OF APPLIANCE START-UP. If the appliance fails to pass the spillage and draft test after the first 60 seconds of start-up, the appliance fails. Remember, both of these tests are done under worst case conditions first, we want the house to fail while we are there to inform the homeowner then, not weeks later when no one is aware. Here are some important details you need to know about draft pressure for the BPI test.

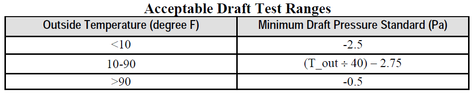

Below are the BPI Standards for the draft test. The hotter the temperature outside, the easier the appliance should draft on its own so the lower the BPI Standard is. To pass the draft test, you need to be at the Minimum Draft Pressure OR MORE NEGATIVE. So let's say it's 80 degrees outside, our minimum draft pressure will be: (80/40)-2.75 = 2 - 2.75 = -0.75 Pa OR MORE NEGATIVE Now let's say the temperature is 20 degrees: (20/40) - 2.75 = 0.5 - 2.75 = -1.75 Pa OR MORE NEGATIVE So as it gets colder outside, the harder it is for the appliance to naturally draft and the minimum draft pressure decreases, or gets more difficult to pass. Worst CaseFor worst case conditions in a CAZ, we want the HIGHEST NEGATIVE NUMBER, remember we want the house to fail while we are there. So we are going to use all the fans (AHU, dryer, bathroom exhaust fans, laundry room exhaust fan and kitchen exhaust fan if it goes outside) to help us create a negative... the highest negative number possible, then do our combustion tests.

We need to test different scenarios with the doors open or closed to see its effect on the house pressure (by watching your manometer). If opening an interior door makes your pressure reading more negative, leave the door open. If opening an interior door makes the CAZ worst case more positive, that is working against our worst case goal (the highest negative number possible, -10 Pa is better than -2 Pa for worst case), so leave the door closed. We need to go around the house and open and close all the interior doors to see their effect on the worst case reading. Start with all the interior doors shut and windows and exterior doors closed. Turn on all exhaust fans, AHU and dryer. Now it's time to check each door. Open an interior door, then go back to your manometer and check it's reading, if it's more negative, leave it open, if it's more positive, go and close it. Then go to the next interior door and open it, go back to your manometer and check the pressure reading (in Pa, not CFM), if it's more negative leave it open, if it's more positive, go and close it. Got the hang of it? You also need to check the affect of the AHU on your worst case. This can be done at the same time as your dominant duct leakage. Dominant duct leakage is done right after you get a baseline reading with all the interior doors open, exterior doors and windows shut, all exhaust fans off and ONLY the AHU on (use high speed if new dual speed AHU). So in other words, only the AHU is on. If you get a negative dominant duct reading (more leakage on the supply), that's is good for our worst case, so leave the AHU on during worst case conditions. If you get a positive dominant duct reading (more leakage on the return), that is working against our worst case, so shut the AHU off for your worst case test. Or you can simply turn the AHU off before or after your interior door check and check your manometer, if the pressure goes down (more negative), leave the AHU on, if the pressure goes up (more positive), shut the AHU off for your worst case conditions. See the full post on worst case and CAZ here. Accounting for the Baseline in Worst Case Conditions

We want a true worst case by not accounting for the baseline.

You can do this by:

Now once you have the house under worst case conditions, you are ready to get your CAZ pressure readings, draft and CO tests done! BaselineA baseline is taken to account for wind and any outside forces that are going on during the time of your audit, TO NORMALIZE ALL YOUR FOLLOWING READINGS.

DepressurizationA house that is depressurized is SUCKING THE AIR OUT. You will be able to feel air coming in through leaky ductwork and air leaks to the attic and outside.

The standard depressurization for a blower door during an energy audit is -50 Pascals. SpillageWhat can cause spillage?

BackdraftingAs we exhaust air from our homes, and as air naturally leaks out of our homes because of wind or the stack effect, it is replaced by outdoor air. If we exhaust a lot of air, we can depressurize the home. Sufficient depressurization can actually pull air and combustion products back down a chimney or any flue, such as that of a gas water heater, and into the house. Because of the harmful substances, such as carbon monoxide, in combustion gases, this depressurization can create a very dangerous situation.

Forces working to depressurize a home include those shown in the figure below, bathroom exhaust fans, kitchen range hoods, and clothes dryers. Other forces not shown in the diagram include the fireplaces, leaky return ducts near combustion equipment, leaky supply ducts outside the conditioned space, wind, and the stack effect (warm air rising in a building tends to depressurize lower areas). If these forces are great enough, they can work to suck air and combustion products back down the chimney or flue and into the house, as shown by the red arrows in the diagram. Source: http://www.epa.gov/iaq/homes/hip-backdrafting.html Unvented Combustion AppliancesUnvented combustion appliances is where a combustion appliance is in a room that does not have any vents connecting it to the outside or a larger CAZ. Naturally drafting water heaters in garages without a high and low vent is an "unvented combustion appliance." If you find an unvented combustion appliance, we need to recommend adding a combustion vent to the outside or a larger CAZ.

Next Section1a. Basic terms and definitions

1b. Principals of energy, air & moisture

1c. Combustion science

|