Passing the BPI Exam With Energy Auditor Training

FREE BPI PRACTICE EXAMPUT YOUR HOME PERFORMANCE BUSINESS ON ROCKET FUELENERGY AUDITOR NEWSLETTERGet the only Energy Auditor Marketing Newsletter with monthly strategies and tactics to grow your home performance business.

|

BPI Written Exam - Section 1 Building Science Fundamentals8. Principles of Combustion: Combustion Analysis, CO

When we refer to combustion, we are talking about gas appliances such as furnace or gas pack heating system, gas water heater, dryer, fireplace, or stove or oven. All these appliances when natural gas, propane, oil or wood to convert the fossil fuel to usable heat for our homes or appliances.

A general formula for the combustion process is below, which is just saying that the fuel oil reacts with oxygen to give carbon dioxide, water and heat. Fuel oil + O2 = CO2 + H2O + heat An important byproduct of the combustion process is CO (carbon monoxide). CO is odorless and deadly and something BPI takes very seriously. Their motto is "Do no harm" and they mean it. During the field exam if you do not turn your ambient CO meter on before you walk into the house... FAIL. If you do not know how to put the house under worst case conditions to test the CAZ... FAIL. CO is formed when there is not enough oxygen delivered to the fuel oil or when the fuel oil and air do not mix well enough, CO will be formed. If you find high undiltued CO levels above BPI actions levels below are some actions to take to try to fix the high CO levels. You may ask why even test for CO espically in high efficiency furnaces where little can be changed to fix the problem? Well the answer is that we are concerned about how the furnace (or appliance) is operating as one piece of a whole system. The furnace's operation can be influenced by dryers, exhaust fans, AHU and duct leakage and room pressures, so we need to take all those into account. Please see the next section to learn more about the actual test that are performed for a combustion analysis. In an oven

Furnace

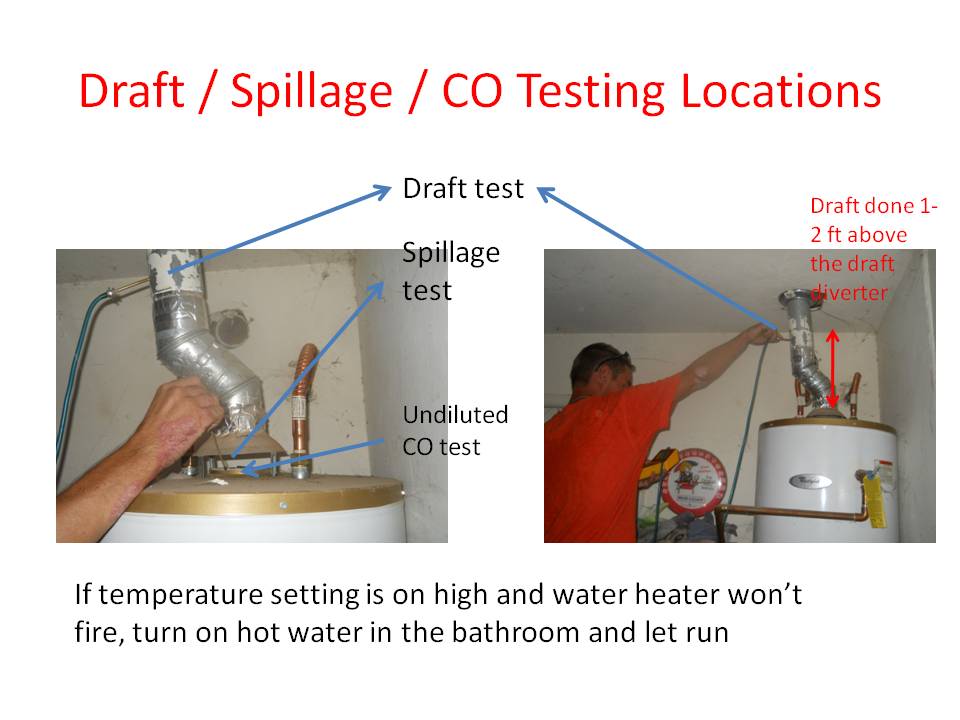

Water heater

BPI has action levels to take for two types of CO readings.

Ambient CO meter that clips onto your belt

A different monitor, allows us to test undiluted CO measurements in the throat of the flue by sticking the metal rod in the hot flue, once the appliance has been on for ten minutes and comes to a steady state.

When BPI says "combustion analysis," we are referring to several tests. These are important to know and get straight as they are often mixed up by trainees.

Numbers 2-4 are all done under worst case conditions. What does worst case actually mean? Let's go to the next section to find out.

Next Section1a. Basic terms and definitions

1b. Principals of energy, air & moisture

1c. Combustion science

|