Passing the BPI Exam With Energy Auditor Training

FREE BPI PRACTICE EXAMPUT YOUR HOME PERFORMANCE BUSINESS ON ROCKET FUELENERGY AUDITOR NEWSLETTERGet the only Energy Auditor Marketing Newsletter with monthly strategies and tactics to grow your home performance business.

|

BPI Written Exam - Section 1 Building Science Fundamentals7. Understand Driving Forces (Including Natural and Mechanical: Pressure, Temperature, Moisture DifferentialTerms:

This is one of my favorite sections because it is so easy to memorize but it has deep implications and can make you look really good in front of a homeowner when explaining why their home gets so dusty, room so hot or floor so cold. The terms above will definitely be on the BPI test, so I would commit them to memory.

Natural forces include:

Mechanical forces include:

You really need to have these topics in this whole section in the front of your mind the entire time you are performing an energy audit. It is too easy for novice energy auditors to concentrate just on the motions, running a blower door test, inspecting the attic for open wall chases and misalignments, walking through the house with an IR camera and think they are doing a good audit. Without understanding these concepts and their applications, an auditor is just putting lipstick on pig. What drives air leakage?The answer is a pressure difference and a hole and you need both of them to get air leakage, if you stop one, you stop the other.

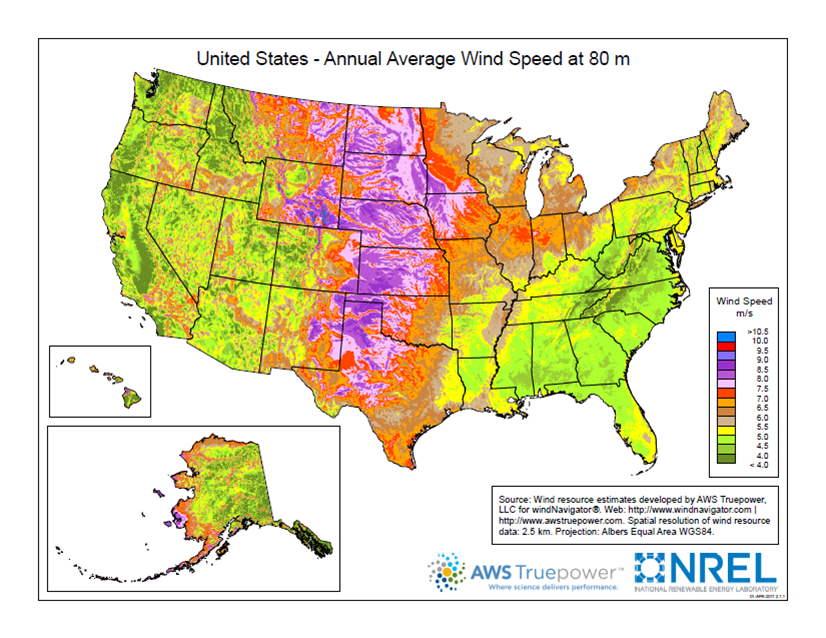

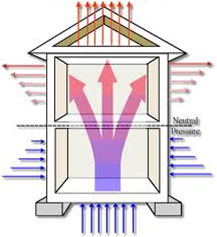

The pressure difference comes from MECHANICAL FORCES like the AHU (air handler unit) or exhaust fans or attic fans if the home is very tight or NATURAL FORCES like wind or the stack effect. The AHU creates a lot of pressure when it kicks on, enough pressure is generated to blow air through all the ductwork up 3 stories or across the house 30 feet. That's why if you are doing a time-and materials contract always start sealing the ductwork connections closest to the AHU, because it is under the highest pressure. Leakage closer to the AHU under 100 Pa of pressure is much more important than leakage 30 feet downstream under 10 Pa of pressure. The room pressure should also be considered because opening and closing doors is essentially like putting a huge dampener on the ductwork to that room if the room pressure is high. High room pressures can contribute to air leakage, dust, allergens and make the HVAC system work harder. What is a high room pressure? You may notice that doors close by themselves when the HVAC system kicks on, that is because it has a high room pressure. By relieving the room's pressure, you reduce the amount of air leaking, dust and increase circulation back to the return. An exhaust fan may not be a blower door, but on a tight home, they can definitely have an adverse effect. A tight home is much more sensitive to doors closing and small fans running than a leaky home because it creates a vacuum effect. This is bad because outside air can come into the home through existing leakage or worse carbon monoxide can enter from an attached garage or backdraft down a water heater or furnace flue and enter the home. You may not have to worry about smaller exhaust fans, but when you go to newer homes that have commercial range hoods suitable for Iron Chef, you really need to be aware. I heard a new Energy Star home was built so tight, that the toilet flushed when the front door was closed... I don't know if that is true, but it is a funny story. Attic fans have been shown to cause the same adverse effects where the attic fan will cause gas appliances to backdraft into the home. Now that is scary. A hole is any connection to the outside or attic space from leaky windows and doors, drywall gaps around exhaust fans, registers and canned lights, and electrical and plumbing penetrations. So to stop air leakage you can either air seal the home or pressure balance the home. Since usually the AHU is going to create some negative or positive pressure every time it runs, air sealing is usually easier (excluding room pressures). Pressure moves from high to lowExamples are:

Temperature moves from hot to coldExamples are:

Moisture moves from wet to dryExamples are

Next Section

1b. Principals of energy, air & moisture

1c. Combustion science

|

The main topics of the BPI BA exam are listed out below. Click on a link that interests you, or you need some brushing up on to learn more on each subject.

1. Building Science Fundamentals 1a. Basic terms and definitions 1b. Principals of energy, air & moisture 1c. Combustion science 2. Buildings and Their Systems 2a. Building components 2b. Conservation strategies 2c. Comprehensive building assessment process 2d. Design considerations 3. Measurement and Verification of Building Performance 3a. Applied diagnostics and troubleshooting 4. BPI National Standards and Project Specifications 4a. Comprehensive building assessment 5. Analyzing Buildings Systems 5a. Comprehensive building assessment 5b. Appliances and lighting 6. Conduct and communications 6a. Conservation strategies |