Passing the BPI Exam With Energy Auditor Training

FREE BPI PRACTICE EXAMPUT YOUR HOME PERFORMANCE BUSINESS ON ROCKET FUELGet the only Energy Auditor Marketing Newsletter with monthly strategies and tactics to grow your home performance business.

|

BPI Written Exam - Section 1 Building Science Fundamentals3. Basics of: Combustion Appliance Venting, Draft, and Combustion Air Including Identification of Proper Sizing/Vent TablesCombustion Appliance VentingAtmospherically vented appliances use the surrounding air to mix with combustion gases for a clean burn. On the other hand, power vented appliances have a dedicated pipe to the outside that draws air into the combustion chamber.

Homes with atmospherically vented appliances have several potential health and safety issues we need to address as part of our energy audit and they are:

Below are guidelines for atmospherically vented flue pipes.

DraftDraft is a naturally occurring process (think stack affect) that vents CO and combustion by-products from a gas appliance through the flue pipe and to the outside. The combustion by-products exit the appliance hot, and so they are carried up the flue stack. Upon appliance start-up however, the combustion gases still need time to warm-up, and this is the highest risk for those gases to back draft and enter into our living space.

That is why we test the draft pressure and spillage of a combustion appliance WITHIN THE FIRST 60 SECONDS OF APPLIANCE START-UP. If the appliance fails to pass the spillage and draft test after the first 60 seconds of start-up, the appliance fails. Remember, both of these tests are done under worst case conditions first, we want the house to fail while we are there to inform the homeowner then, not weeks later when no one is aware. Here are some important details you need to know about draft pressure for the BPI test.

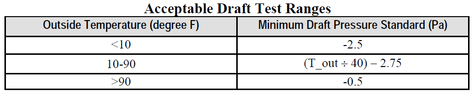

Below are the BPI Standards for the draft test. The hotter the temperature outside, the easier the appliance should draft on its own so the lower the BPI Standard is. To pass the draft test, you need to be at the Minimum Draft Pressure OR MORE NEGATIVE. So let's say it's 80 degrees outside, our minimum draft pressure will be: (80/40)-2.75 = 2 - 2.75 = -0.75 Pa OR MORE NEGATIVE Now let's say the temperature is 20 degrees: (20/40) - 2.75 = 0.5 - 2.75 = -1.75 Pa OR MORE NEGATIVE So as it gets colder outside, the harder it is for the appliance to naturally draft and the minimum draft pressure decreases, or gets more difficult to pass. Combustion Air SizingThis section on combustion air room sizing is only for atmospherically vented appliances which draw air from inside the house, sealed combustion units draw air directly from the outside and you do not need to worry about proper room sizing.

All atmospherically drafted appliances require combustion air from the room where the appliance is located. In other words, the appliance needs to breath in fresh air from the room to:

If a room is "too small" for the appliance, the appliance may not draft properly. An easy test to see if a room is "too small" is to take a draft pressure, then open a window in the same room as the appliance and take another draft pressure... if opening the windows decreases the draft pressure (makes it more negative), more combustion air may be needed. BPI Standards for combustion air supply is 50 cubic feet of air per 1,000 BTU. You will need two pieces of information to check if your room is big enough for the combustion appliance.

There must be two combustion vents, one 12-inches from the ceiling and one 12-inches from the floor in the room of the combustion appliance. Let's do an example. What is the volume required for a 40,000 BTU gas water heater in a garage 20x30x10 feet?

Let's do another example, but add a 100,000 BTU furnace in the same garage as our 40,000 BTU water heater.

Let's keep going, but take off the interior garage door so our area now includes part of the house, another 400 sq ft of house with 10 ft ceilings.

(You can also size a room if you are designing a new home with an atmospherically drafted water heater but that is less common for energy auditors as we deal mainly with existing homes.) That is the reason why it is code to have upper and lower vents in a garage with an atmospherically drafted water heater for example (something you can check for although I have only found one home that only had one high vent in a garage and we installed a new low one). Next Section1a. Basic terms and definitions

1b. Principals of energy, air & moisture

1c. Combustion science

|