Passing the BPI Exam With Energy Auditor Training

FREE BPI PRACTICE EXAMPUT YOUR HOME PERFORMANCE BUSINESS ON ROCKET FUELENERGY AUDITOR NEWSLETTERGet the only Energy Auditor Marketing Newsletter with monthly strategies and tactics to grow your home performance business.

|

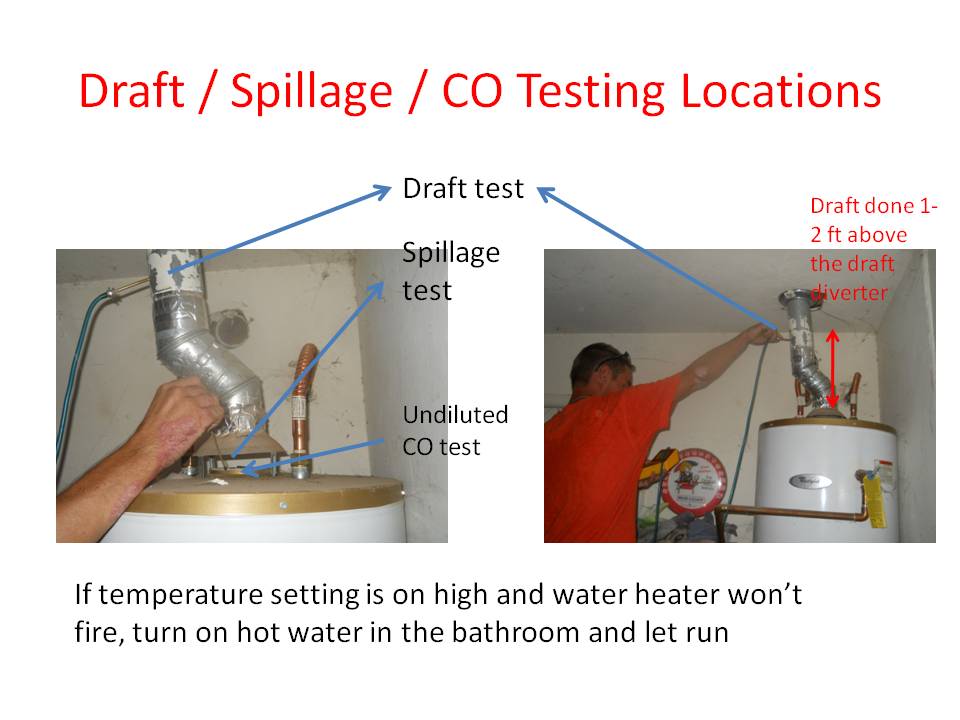

BPI Written Exam - Section 1 Building Science Fundamentals2. Carbon Monoxide (CO) Testing of Combustion AppliancesCarbon monoxide is always measured under worst-case conditions first, then if the draft/spillage/CO limits are above BPI standards, measure CO again under natural conditions (with all the fans off).

Carbon monoxide needs to be measured from all gas appliances including the:

If the appliance is atmospherically vented, you can measure undiluted CO right in the throat of the flue. CO testing for an atmospherically furnace and water heaterYou will find more atmospherically vented water heaters than furnaces, but you may run into one every 100 audits or so. The order of your CO test for an atmospherically vented furnace (old ones) and atmospherically vented water heater goes like this:

CO testing for a power vented furnace or water heaterA power vented furnace or water heater will have a small fan you can identify to push the CO and combustion gases out of the flue. There is no smoke or draft tests on these appliances because there is no diverter... the appliance does not use the ambient air to help carry combustion gases outside, it forces the combustion gases outside.

You can still do a CO test on a power vented appliance, but it is at the flue terminal. In Arizona, energy auditors do not have to risk going on the roof of a two story home or potentially crack a tiled roof house to get a CO reading. However, if the flue terminal is on a flat or shingled roof or on a side wall, a CO reading is expected. Here are the steps for a power vented appliance:

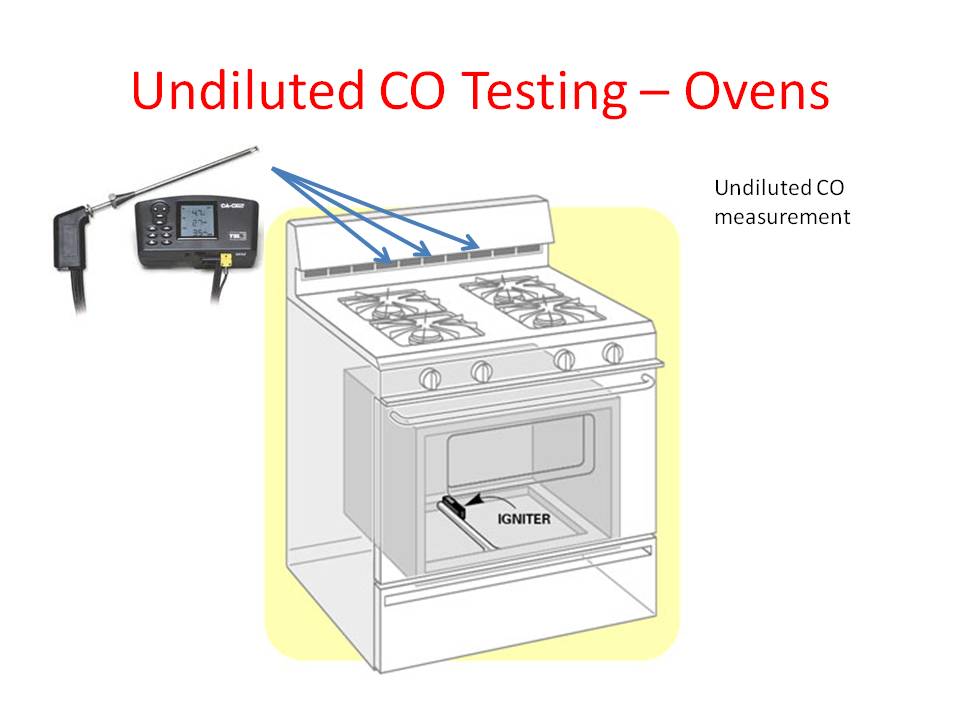

CO testing for an ovenKitchens are not required to have an exhaust fan so don't be alarmed if your microwave does not exhaust outside when you open the cabinet.

If you get a high CO reading

Next Section1a. Basic terms and definitions

1b. Principals of energy, air & moisture

1c. Combustion science

|